How can we ensure the safety and reliability of the Marine Dual Fuel Generator Set during daily use?

2025-11-13

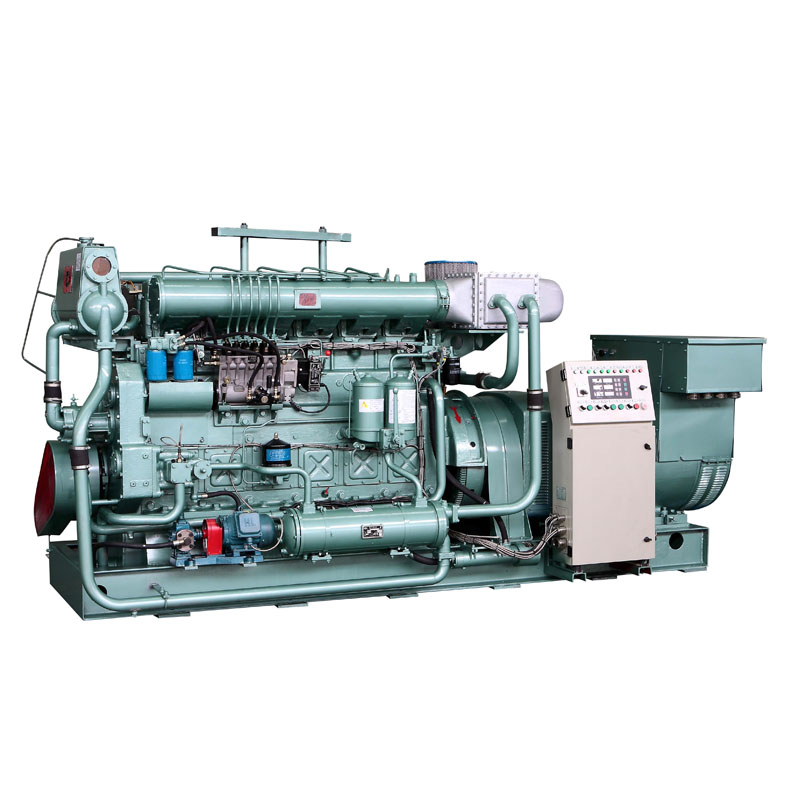

The Marine Dual Fuel Generator Set is the "electric heart" of the ship, capable of running both diesel and natural gas. While convenient, its operation requires meticulous attention. Both experienced and new crew members must thoroughly practice the operating procedures before starting work to avoid chaos at sea. This is the first hurdle for safety.

Strict Control of Fuel "Entrance"

Whether it's diesel or natural gas, it must be "clean" before entering the Marine Dual Fuel Generator Set. Otherwise, impurities will clog the fuel injectors, damage the cylinders, and cause the unit to either lack power or completely shut down. The diesel tank should be drained regularly to remove sediment; the water and sludge at the bottom should not be left. The natural gas filter is even more critical; it must be removed and blew out weekly, and replaced promptly if it becomes dirty. This is like drinking clean water to avoid stomach upset.

Daily Checks

The safety and reliability of the Marine Dual Fuel Generator Set relies entirely on daily "check-ups." Before starting the engine each day, the crew must walk around the unit: checking the oil and gas pipes for leaks, verifying the coolant level, and listening for any unusual noises from the fan. These actions take less than five minutes but allow for timely detection of problems. For example, if an oil pipe joint is found to be slightly damp, the clamps are tightened immediately; if the coolant level is low, soft water is added promptly—seawater, containing salt, will corrode the water tank.

Providing "Anti-Corrosion Protection"

The salt spray at sea is both humid and corrosive, making the metal casing and terminals of the Marine Dual Fuel Generator Set prone to rust. Excessive rust can lead to electrical leaks and poor contact. Therefore, routine anti-corrosion measures are essential. The Marine Dual Fuel Generator Set's casing is coated with anti-rust oil monthly, the terminals are sealed with Vaseline, and areas installed outdoors are covered with rain covers. Experienced ship owners also install dehumidifiers on the Marine Dual Fuel Generator Set, especially in southern waters where the cabin is humid during the rainy season; running a dehumidifier helps reduce rust on internal parts. Just like a house by the sea needs anti-corrosion paint, putting in extra effort can extend the lifespan of your Marine Dual Fuel Generator Set by several years.

Don't block the cooling channels

The Marine Dual Fuel Generator Set gets hot during operation, and the heatsink is like its "sweat glands." If it gets clogged with oil or dust, the heat can't dissipate, causing it to overheat and shut down; in severe cases, it can even burn out the coils. Therefore, the heatsink needs to be blown out frequently and wiped regularly, especially on ships with heavy oil fumes in the engine room, where it should be blown out weekly with a high-pressure air gun. Don't forget the fan and cooling pump either; check them immediately if you hear any unusual running sounds, and add grease if the bearings are low on lubrication.

Regular "major maintenance."

Routine checks aren't enough; you also need to perform "deep maintenance" on your Marine Dual Fuel Generator Set regularly—generally, change the oil and oil filter after 500 hours of operation, and disassemble and inspect the cylinders and clean carbon deposits after 1000 hours. These maintenance services are essential, just like regular checkups for people, preventing minor problems from arising in advance.